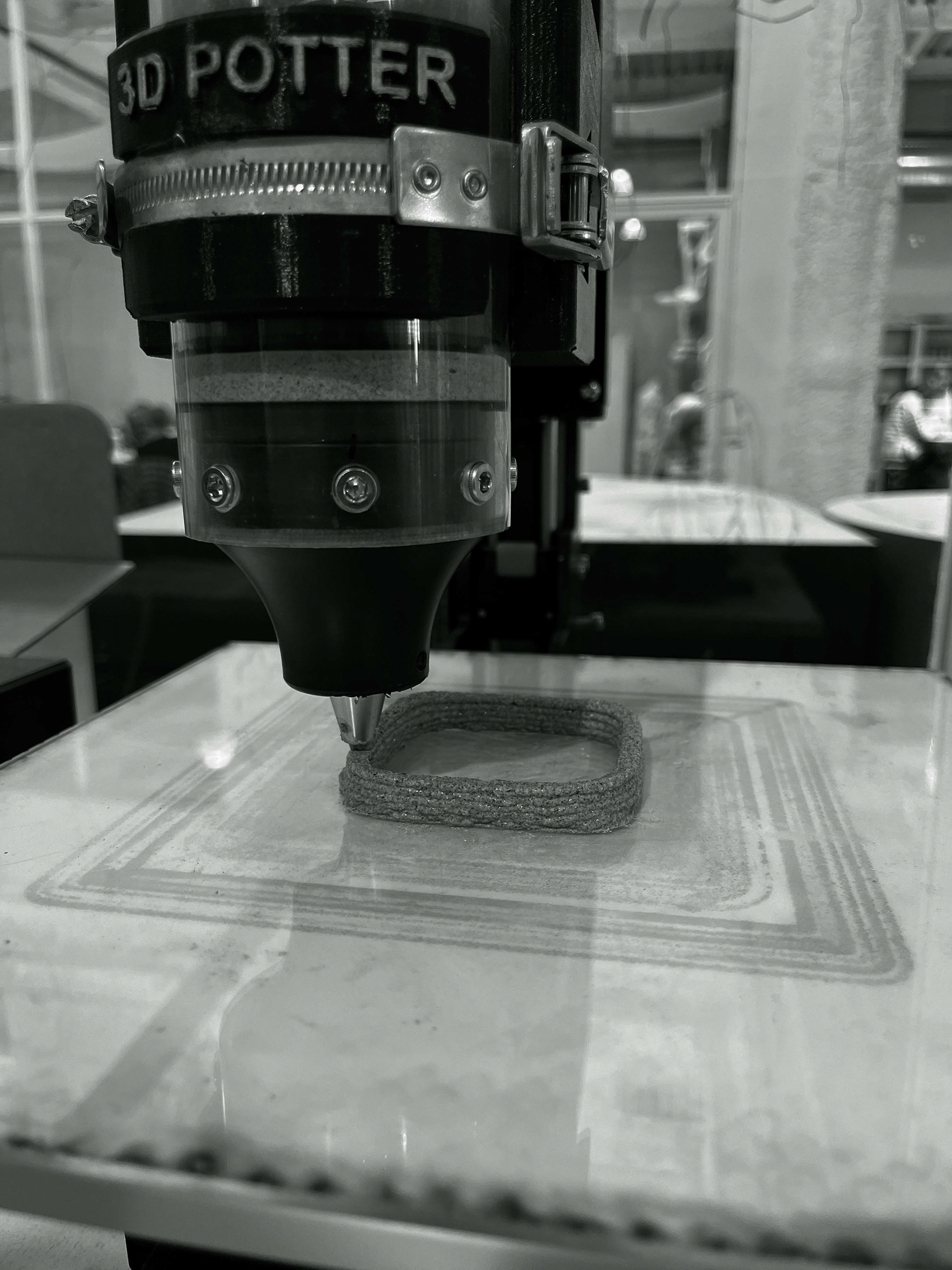

Digital manufacturing plays a crucial role in enabling the creation of seedbeds using biomaterials. 3D printing, for example, can be used to manufacture seedbed structures tailored to the specific needs of each type of crop. Furthermore, the versatility of biomaterials allows for the creation of biodegradable and compostable seedbeds, reducing reliance on conventional plastics and contributing to the mitigation of environmental pollution.

Research and development of biomaterials for seedbeds can also benefit from digital manufacturing. Advanced technologies enable rapid experimentation and prototyping to develop more efficient and resilient biomaterials. This is essential to ensure that seedbeds made with biomaterials meet the necessary standards of strength, durability, and the ability to support plant growth optimally.

In terms of economic sustainability, the combination of digital manufacturing, seedbeds, and biomaterials can drive the creation of specialized local industries in the production of these innovative seedbeds. This not only fosters autonomy and resilience in agricultural communities but also promotes the adoption of more ecological and resource-conscious farming practices.

SEEDBED

FLOWERPOT